Trackman in Your Industry

Reliable tracks are essential for peak performance in agriculture and construction. We engineer for maximum uptime and efficiency. See the difference our expertise makes on the job.

Why Trackman Tracks?

Over 30 Years of Proven Performance

Trusted by farmers and OEMs alike, Trackman has been keeping farmers moving since 1992—delivering durability and performance you can count on season after season.

Engineered for Tough Conditions

From rugged fields to extreme weather, Trackman’s fully molded tracks are built to withstand the harshest environments without compromising on traction or ride quality.

Industry-Leading Rubber Compounding

Our in-house rubber compounding expertise means stronger, longer-lasting tracks with superior resistance to wear, chunking, and cracking.

Proudly Made in the USA

Every track is designed, tested, and manufactured in St. Marys, Ohio. When you buy Trackman, you support American jobs and American farming.

Key Features and Benefits

Our fully molded rubber tracks and wheels are designed to deliver consistent, high-performance results across diverse applications. Experience these key advantages:

Unmatched Durability

- Built with high-grade materials to withstand tough conditions.

- Extends equipment lifespan and minimizes replacements.

Optimized Efficiency

- Designs reduce friction and enhance power transfer.

- Improves fuel efficiency and overall equipment performance.

Enhanced Operator Comfort

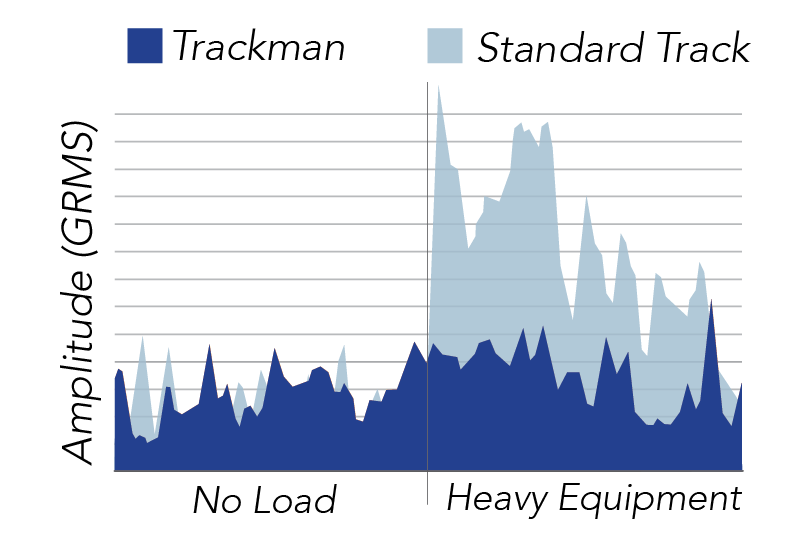

- Advanced technologies like Anti-Vibration Technology™ reduce fatigue.

- Improves comfort and productivity during long workdays.

Corrosion Resistance

- Patented galvanized cable and corrosion resistant materials extend product lifespan.

- Protects against harsh environments.

Why Choose Tracks Over Tires?

Track systems offer unparalleled advantages across a wide range of applications. Whether in agriculture or construction, our custom tracks enhance equipment performance and productivity. Here are some key applications:

Superior Traction

Tracks deliver better ground contact and grip, especially in wet, muddy, or uneven terrain, reducing slippage and improving performance.

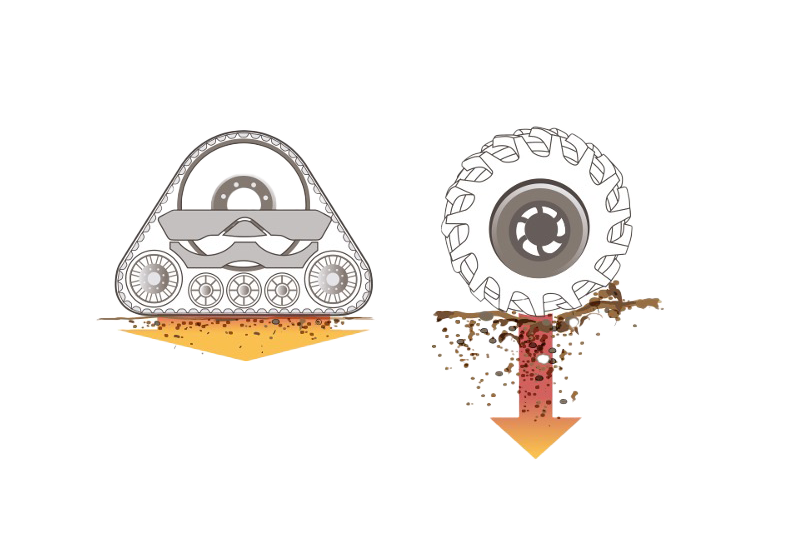

Minimized Soil Compaction

With a larger surface area, tracks distribute weight more evenly than tires—protecting soil health, preserving yields, and maintaining field conditions.

Smoother Ride & Operator Comfort

Track systems absorb more vibration and shocks, leading to a more stable, comfortable ride—even over rough or rutted fields.

Increased Pulling Power & Efficiency

Tracks offer enhanced drawbar pull and less power loss, translating to greater fuel efficiency and more effective operation of heavy implements.

Reduced Maintenance Downtime

Track systems experience fewer punctures and flats compared to tires, keeping machines in the field longer with less unplanned maintenance.

-

View Product

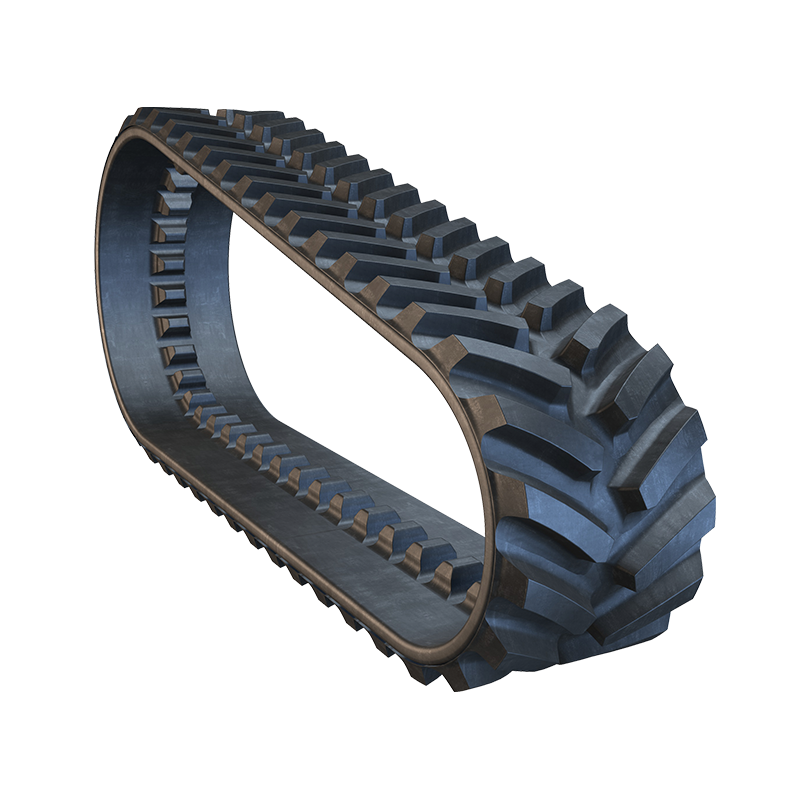

Quiet Strength. Seamless Performance. Trackman friction drive rubber tracks are built for smooth, reliable operation with minimal vibration and maximum efficiency. Trusted by OEMs and farmers alike, these tracks deliver high performance in the field — season after season.

-

View Product

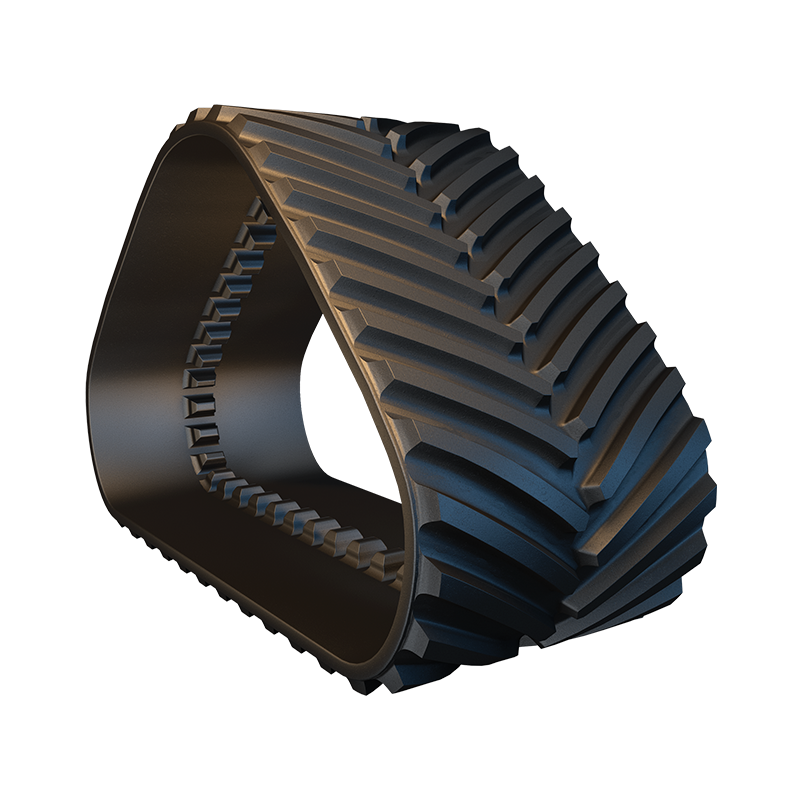

Ultimate Grip. Precision Power. When you need uncompromising traction, Trackman positive drive rubber tracks rise to the challenge. Engineered for heavy-duty applications, they provide exact power transfer, reduced maintenance, and extended service life.

-

View Product

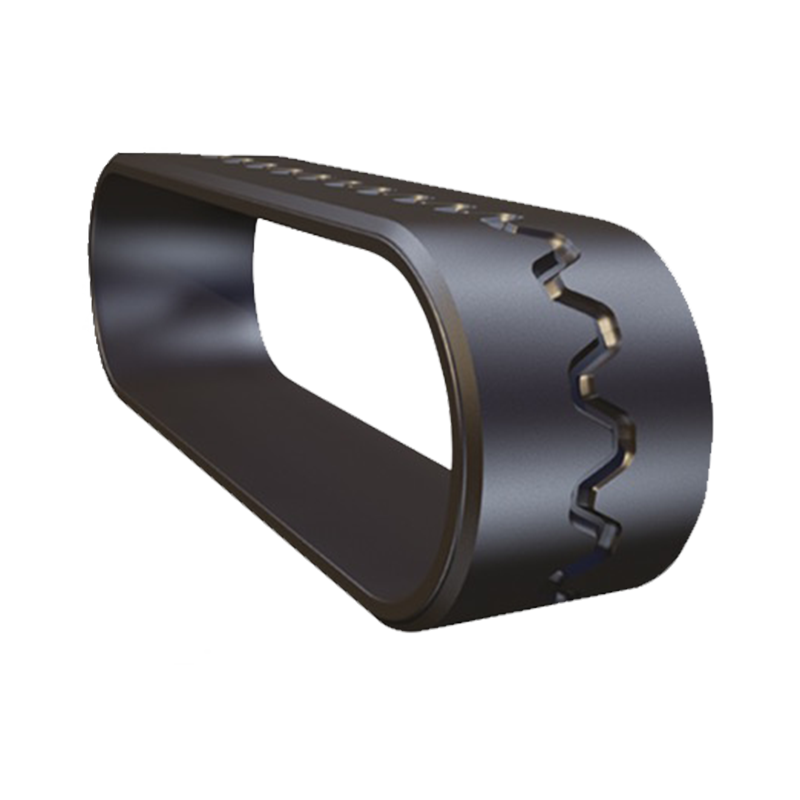

Industry-leading paver track innovation. Durable designs, smooth track technology, and MAXXTUFF™ steel belting. Delivering reliable performance now.

-

View Product

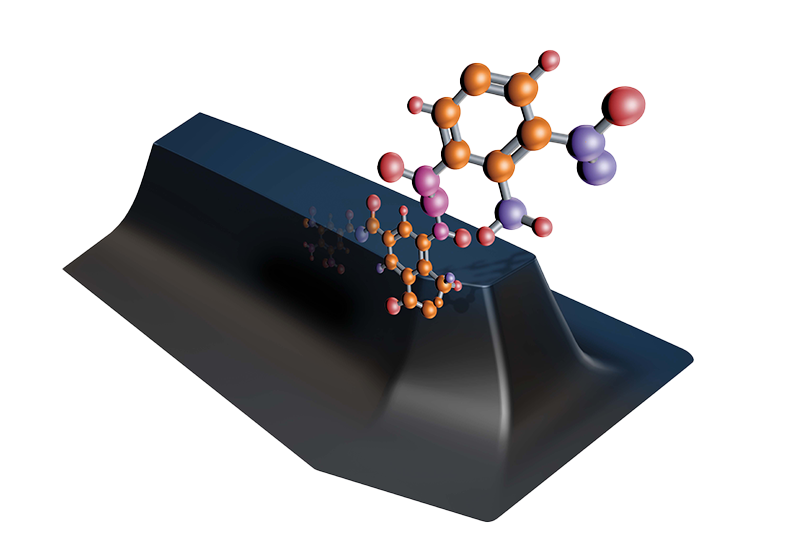

Trackman leads in innovative new and re-manufactured polyurethane wheels for both positive and friction-drive systems. Reduce friction, operate cooler, and extend track life.

-

View Product

Grain cart tracks, combine tracks, sprayer tracks, planter tracks, hay conditioner mower rolls, rubber compounding, and bladder bags.